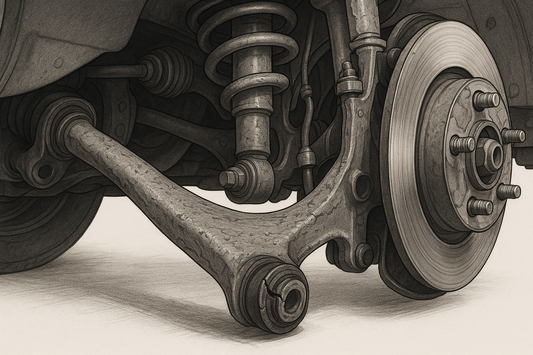

Worn control arm bushings can lead to clunking noises, unstable steering, and uneven tire wear. While replacing them might seem daunting, a DIY approach can save hundreds in labor costs—if done correctly. In this guide, we’ll walk you through the process of changing control arm bushings safely and efficiently, while highlighting why Loosoo’s high-performance bushings are the go-to choice for longevity and value.

Tools You’ll Need

- Hydraulic jack and jack stands

- Socket wrench set (14mm–21mm)

- Ball joint separator or pickle fork

- Torque wrench

- Loosoo’s Bushing Press Kit (optional but recommended)

- Safety gloves and goggles

Step-by-Step Replacement Guide

1. Safety First

- Park on a flat surface, engage the parking brake, and chock the rear wheels.

- Lift the vehicle and secure it on jack stands.

2. Remove the Control Arm

- Step 2.1: Disconnect the ball joint using a ball joint separator.

- Step 2.2: Unbolt the control arm from the frame and steering knuckle.

3. Press Out Old Bushings

- Use Loosoo’s Bushing Press Kit to avoid damaging the control arm:

- Secure the arm in a vise.

- Align the press tool with the bushing and slowly extract it.

4. Install New Loosoo Bushings

- Step 4.1: Clean the control arm bore with a wire brush.

- Step 4.2: Apply a thin layer of silicone grease to the new bushing.

- Step 4.3: Press the bushing in evenly until seated.

5. Reassemble and Torque

- Reattach the control arm and ball joint.

- Tighten bolts to manufacturer specs (typically 80–120 ft-lbs).

6. Post-Installation Check

- Test-drive to check for noises.

- Get a wheel alignment to prevent uneven tire wear.

Why Loosoo Bushings Outperform Competitors

Loosoo’s bushings solve common pain points with innovative engineering:

1. Hybrid Rubber-Polyurethane Design

- Durability: Lasts 2–3x longer than OEM rubber bushings.

- Noise Reduction: Eliminates squeaks with embedded lubricant channels.

2. Corrosion Resistance

- Stainless Steel Sleeves: Prevent rust-induced binding in snowy or coastal climates.

3. Cost Efficiency

- Price: 40–60% cheaper than dealership parts (e.g., Ford OEM bushings cost $80–$120 vs. Loosoo’s $35–$65).

- Warranty: Lifetime replacement if bushings crack or deform.

Case Study: Loosoo Bushings Save Taxi Fleet $15k Annually

A New York taxi fleet replaced 200+ failing bushings with Loosoo’s Heavy-Duty Bushings:

- Lifespan: 100k+ miles vs. 30k miles with budget brands.

- Savings: Reduced annual maintenance costs from $22k to $7k.

3 Costly Mistakes to Avoid

- Hammering Bushings Out: Damages control arm bores—use a press tool.

- Ignoring Torque Specs: Over-tightening warps bushings; under-tightening causes slippage.

- Skipping Alignment: Misaligned suspension accelerates bushing wear.

FAQ: Control Arm Bushing Replacement

Q: Can I replace bushings without removing the control arm?

A: Not recommended—access is limited, and improper pressing risks damage.

Q: Are Loosoo bushings compatible with lifted trucks?

A: Yes! Custom bushings are available for 2–6" lifts.

Q: How often should bushings be replaced?

A: Inspect every 50k miles; replace if cracked or softened.

Replacing control arm bushings is a manageable DIY job with the right tools and parts. While OEM and generic bushings wear quickly, Loosoo’s hybrid bushings deliver unmatched durability and noise reduction at a fraction of the cost—proven in daily drivers and commercial fleets alike.